The city of Loreto, located in Central Italy, is one of the most renowned cradles of Italian craftsmanship, especially when it comes to rosaries. These simple religious objects are the result of centuries of artisan tradition and know-how. The practice of making rosaries stood the test of time thanks to the matrilineal inheritance of the techniques passed from mothers to daughters.

In Loreto, where our rosaries come from, women are still in charge of preserving this ancient craft. In Italian, they are called "incatenatrici," — from "incatenatura," which refers to the very core principle of making a rosary, that is, the binding of beads. This work requires a lot of patience and ability. The most experienced craftswomen make about 4 or 5 rosaries per hour, meaning it takes more or less 15 minutes to make each rosary by hand.

The anatomy of a rosary

A standard rosary has 59 beads: Hail Mary beads appear in five groups of ten, called "decades"; the six single beads are the so-called "Our Father" beads; finally, the group of three on the loose end of the rosary are the "Antiphon Beads."

Ideally, we can represent a rosary as a loop connected by a centerpiece to a pendant segment ending with a crucifix. Originally, rosaries were made of the cord, whose knots designated the number of prayers to pronounce. From the 12th century on, the design and purpose of rosary beads underwent several changes. Other techniques and materials were introduced, such as silk and pearls. Nowadays, the choice for a worshipper is arduous, for an incredibly rich collection of rosaries is available on the market. The most significant innovation, however, is undoubtedly the technique employed to produce the metal rosaries.

How rosary making is done

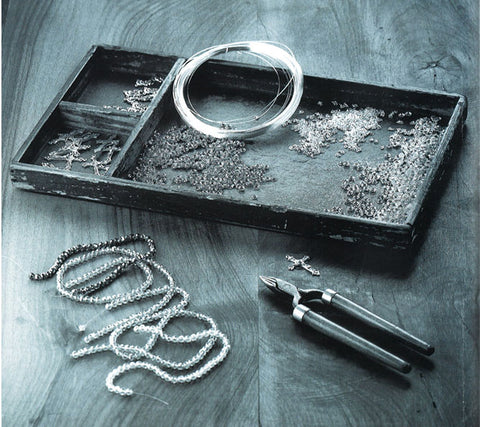

Nowadays, the vast majority of rosaries are made of brass, Sterling Silver, or Gold. This kind of rosaries is commonly composed of beads, eye pins, a connector, and a crucifix. The "Hail Mary" beads are strung together with half-hard wire pins of a couple of centimeters and shaped like a question mark. To obtain this kind of shape, we roll the wire with a special plier that has a flat surface.

To assemble a decade, we slip an eye pin through a bead, then make a loop on its straight side, and repeat this procedure for the other beads, connecting each time the new bead to the previous one.

The "Our Father" beads are bound to the decades by a Rolo-chain segment, containing three or more links. The last part of making a rosary consists of putting all these elements together. After assembling the rosary loop, its loose ends are joined together with the centerpiece — also known as "connector" or "medallion," — to which we add a pendant segment with the crucifix. The connector of our Sterling Silver rosaries is usually a Miraculous Medal, powerful and beautiful as it is.

Job's tears rosary

Just one more curiosity about the rosary making: one of the "old-school" materials used to make rosary beads were the hard-shelled seeds of a tropical plant called Coix lacryma-jobi. The shape of its pearly white beads recalled the teardrops of Job, a Biblical figure that suffered greatly.

We hope that you enjoyed reading this blog as much as we enjoyed interviewing our artisans. We also hope that praying with our rosaries will make you feel the great mastery, care, and devotion employed to create your instrument of faith.

Related articles: